Welcome To Hangfu !

Multi-nozzle steam ejector

Multi-nozzle steam ejector is an efficient steam pressure lifting equipment taking advantage of steam step utilization, which is widely used in the energy saving and emission reduction projects of coal-fired power plants, thermal power plants, petroleum, chemical, sugar, paper and other industries as well as in the technical reformation projects of transforming large-scale condensing steam turbin into heat-supply unit.

The company has achieved China's national patent, the number of which is ZL2008 2012 0719.9.

The enterprise possesses independent intellectual property rights.

Operating principle: pressure lifting equipment is drived by higher pressure steam which through the nozzle to form high speed jet, then to come into being low pressure area. There is a pressure difference between the low pressure area and the drawn steam, by which low pressure steam is pumped in. Two strands of steam flow mix sufficiently and then lift the pressure. The output of the steam pressure is higher than the drawn steam pressure, so as to achieve the purpose of the pressurelifting.

According to the users’ flow variation range , multi-nozzle steam ejector can adopt single or multiple nozzle structureto adjust the steam flow. The steam flow adjusting range is from 10% to100%.

Injection coefficient μshows the injecting capacity of multi-nozzle steam ejector. The value of μdepends on the ratio between low pressure drawn steam flow Gh and high pressure steam flow Gp. That is to say μ=Gh/Gp.

Application example

In October, 2010, in the heat supply reformation project of No.5 and No.6 unit(2*300MW) in Tianjia’anPower Plant, Anhui Province, China, 144 small boilers, the original heat supply in surrounding areas were dismantled. Instead, Tianjia’anPower Plant is the central heating.The main equipment in the reformation project is the multi-nozzle steam ejector that is produced by the company.

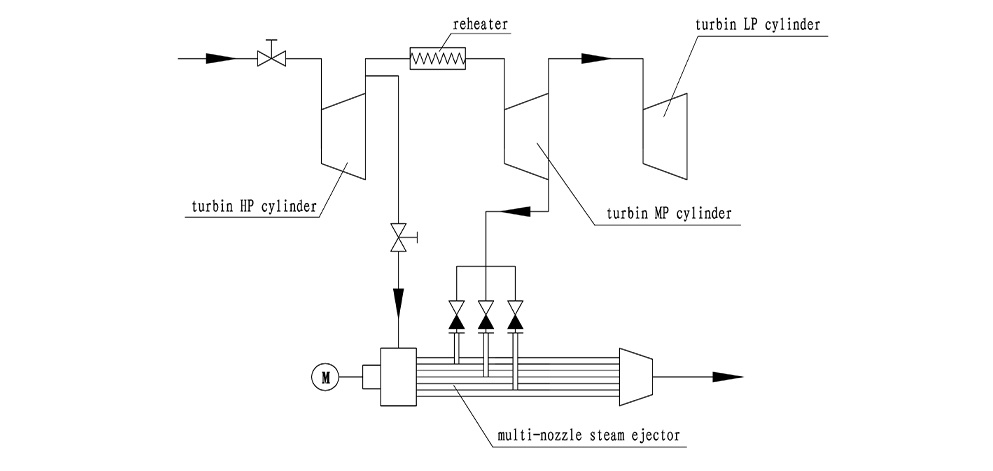

As shown in the figure, lead out an extracting steam pipe from the exhaust steam pipe of the turbine high-pressure cylinder as the highpressure driving steam(3.5MPa/320℃)in multi-nozzle steam ejector. Lead out an extracting steam pipe from the connecting pipe between turbin mid-pressure cylinder and turbin low-pressure cylinder as the lowpressure drawn steam(0.7-0.8MPa/340℃)in multi-nozzle steam ejector. After the two strands of steam flow mix sufficiently and lift the pressure, the output of the steam pressure is 1.0 to1.2 MPa. Through the desuperheater,the desuperheated steam enter external steam tank to meet theneeds of the users.

The maximum design flow of single ejector in the project is 82.5t/h. According to the user's actual steam consumption, heating power plant can open or close the nozzles of the ejector one by one which adjust the output flow rate from 20% to 100% range and with stable export parameter.

The injection coefficient μ of the efector is 1. That is to say the consumption of the highpressure driving steam is the same as that of the lowpressure drawn steam. Each of them is 40 t/h. Another 2.5 t/h is the consumption of cooling water(1.6 MPa / 40 ℃).

On the meeting of project completion and acceptance, hosted by Energy Administration in Anhui province in China, thereformation project is all agreed that the technology is serious and careful, put into operation is normal and various parameters display equipment running in good condition. 150,000 tons of standard coal can be save as well as about 1,600 tons of sulfur dioxideemissions and approximately 21,000 tons of smoke emissions can be reduced every year.

Compared with easily using reducing temperature and pressuredevice to reduce the qualityof high parameter steam, the way that the ejector and the steam turbine work together to supplysteam can save more energy: Compared with drilling a hole on the steam turbine to draw steam and supplysteam, the way is more economical and flexible.

The way that the ejector and the steam turbine work together to supplysteam can use new boiler steam as ejector’s working steam, and also can employ the reheat steam between high-pressure cylinder and mid-pressure cylinder to do the same. The original turbin bleeding point or the back-pressure machine exhaust point can supply steam to the low pressure drawn steam.

InChina, the company has reformed dozens of central heating projects. At present, each ejector produced by the company all work in good condition.

ordering instructions:

high pressure working steam pressure

high pressure working steam temperature

low pressure drawn steam pressure

low pressure drawn steam temperature

outlet steam pressure

outlet steam temperature

outlet steam flow

cooling water pressure

cooling water temperature